Overhaul4 What Overhaul is like for Sailors Part2

Introduction

This is the second post about what overhaul is like for sailors and why it causes them to struggle. I plan several more posts on this topic. The focus of this installment is: what you don’t know about the overhaul schedule hurts (work and schedule knowledge asymmetry).

What You Don’t Know Hurts

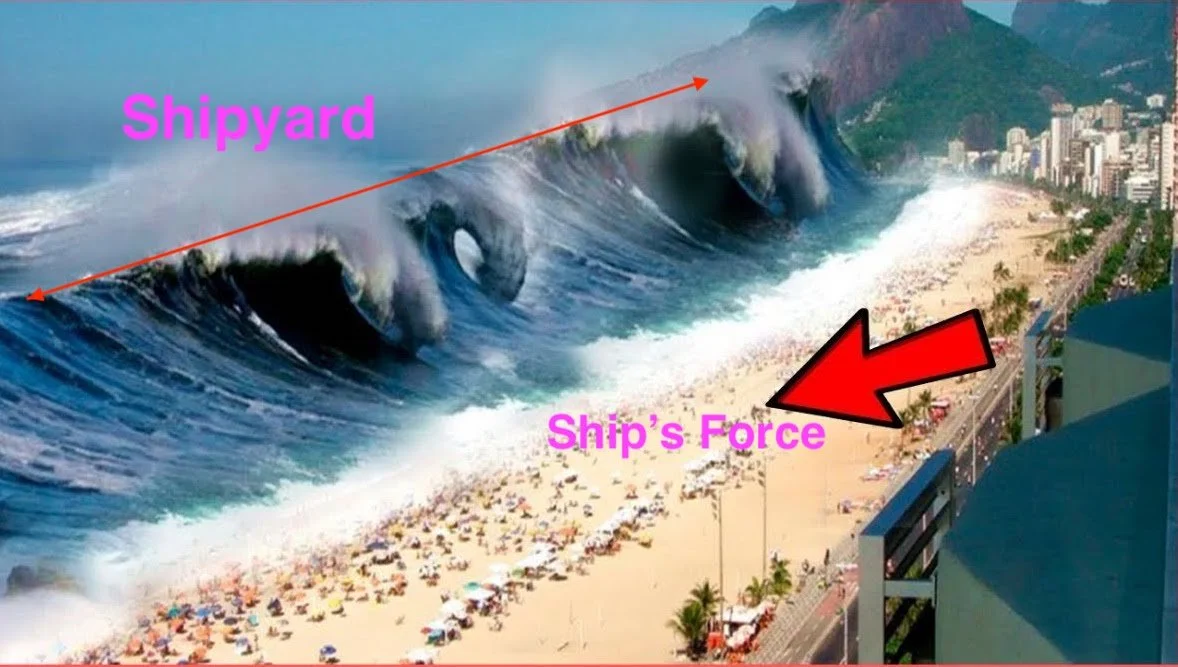

The knowledge gap regarding the work between the shipyard (SY) and the ship’s crew in any ship maintenance period is vast. Shipyard managers plan and analyze the work for months, sometimes years before the availability starts. They know the intricacies of the plan, the critical work, and the priorities (AKA “the critical path”). They’re professionals and most have worked on several overhauls in different positions. That can be a bad thing if too many people are in new positions, but that is another issue. Despite or possibly because of their deep knowledge of overhaul processes (the curse of knowledge), they forget that everything is new and foreign to ship’s force. A large fraction of every ship’s crew doesn’t have ANY overhaul experience and the small number that do have tried very hard to forget it to dull the pain. Ship’s force’s (SF) lack of experience strongly affects their responses to SY support requests (demands, actually).

The tsunami of temporary services, laydown areas, scaffolding, hull cuts (“SMOs, see my previous post), and deckplate removal that occur in the first few weeks of an overhaul is overwhelming. The few ship’s force (SF) supervisors who become familiar with the contents of the Availability Work Package only have a general idea of the work because the details aren’t in the AWP. No one actually “reads” the AWP. This was my personal experience as a member of the crew beginning of several availabilities and when I was assigned to an overhaul a week before it started in my first Engineering Duty Officer (EDO) shipyard tour. As a new EDO project team member, I listened to a shipyard foreman ask for a doghouse installation at production support meetings for two weeks before I even knew what a doghouse was!

The asymmetry in knowledge about the work goes beyond terminology. This is frustrating for the crew. While shipyard managers have been planning job sequences, reducing job conflicts, and allocating services and manning to do the work (“resources” in shipyard language), the crew has been focused on their regular work of operating, training, cleaning, planning their work, cleaning (they do a lot of cleaning), and maintaining. Their focus on overhaul typically begins the day they arrive in the shipyard.

Maintenance periods are scheduled as if crew mission changes operate under the control of a simple switch. This isn’t “smart” from an external observer’s point of view, but it probably can’t be otherwise. External observers with unlimited power to make changes are in very short supply. I’ve done pre-overhaul training for the crew and they usually can’t process what’s in store for them no matter how good your PowerPoint graphics are.

Position One of the crew performance switch, NORMAL, is performing their normal work underway pursuant to the ship’s mission. The maintenance period begins and, voila (not pronounced “vee-OH-la”), the switch goes to position Two: SY SUPPORT. In this position, the crew is supposed to support everything the shipyard needs without delay AND continue doing all their other work.

Shipyard (SY) managers and members of shore-based Navy staffs frequently complain that the ship’s crew doesn’t know what is in the AWP. As if that would make a difference! I have studied more than one AWP as a member of the crew, as a maintenance planner, and as a shipyard manager. Each time, after regaining consciousness and emerging from the concussion protocol, I found the experience unfulfilling. First, an AWP is written in code that only maintenance planners understand. It’s a tool for them and maintenance providers, not the crew. Second, details of HOW the work will be performed, the stuff that really matters, aren’t in the AWP. What production work really happens and when is in the schedule, which is written in a different code that even Alan Turing would have found troublesome. Oh, and the schedule changes daily based on obstacles, technical problems, material shortages, work stoppages, and new work.

The crew needs to know about the work in the availability, but only enough to have a general idea of what is going to happen. It is impossible for them to learn from the AWP what support they’ll have to provide. Ship’s force supervisors can’t even use the schedule (a separate document) to plan their support of the shipyard very well because almost none of their support work or the resources to perform it is included. It can’t be.

SY managers don’t know and couldn’t dictate if they did (i.e., they wouldn’t be allowed to) how SF provides support for the SY: how many people are needed with which skill sets to hang tags, line up systems, and operate equipment. They don’t know how many watchstanders are needed for which operations, who supplies fire watches, how many people will have to be loaned to other departments to support ship-wide work, how many people will be needed for work document processing (and thus unavailable for other work), etc. This work is at least 50% of what sailors do in overhaul, but it is treated like a black box, which makes it unmanageable.

Even worse than the problem of being unable to define and schedule SY support work, some people get dangerously enthusiastic about improving other aspects of SF work in availabilities. I define “dangerous enthusiasm” as being confident that you know exactly how to solve a problem when you are totally ignorant of its details. This is the Kruger-Dunning Effect (see references for Overhaul1). One of the many holy grails of improved overhaul performance is making some part of the workforce more “productive.” This productivity is NEVER focused on improving SY support by SF because even the “ignorant and unaware of it” types realize that it is really hard. Trying to get more tile installed by the sailors sounds a lot easier.

Next Post

I’m having way too much fun writing (my most important motivation for writing) so I’ll stop. In my next post, I will explain why “supporting the shipyard” is a lot harder for the crew than I have described in this post.

Brief comment on the Overhaul3 post. I just had my teeth cleaned. Now I know why wearing safety glasses is a good idea. All the water blasting on your front teeth creates spray that flies into the air and right into your face! That, and the hygienist told that she read about a case where the dentist dropped the moving hypodermic and punctured a person’s eyeball.